Decoding the Schedule 40 Pipe Wall Thickness Chart: A Complete Information

Associated Articles: Decoding the Schedule 40 Pipe Wall Thickness Chart: A Complete Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Decoding the Schedule 40 Pipe Wall Thickness Chart: A Complete Information. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Decoding the Schedule 40 Pipe Wall Thickness Chart: A Complete Information

Schedule 40 pipe, a ubiquitous presence in plumbing, industrial functions, and development tasks, is outlined by its standardized wall thickness. Understanding this thickness is essential for choosing the suitable pipe for a particular utility, making certain structural integrity, and complying with related constructing codes. This text delves into the intricacies of the Schedule 40 pipe wall thickness chart, exploring its development, functions, limitations, and the significance of correct choice.

Understanding the Schedule System:

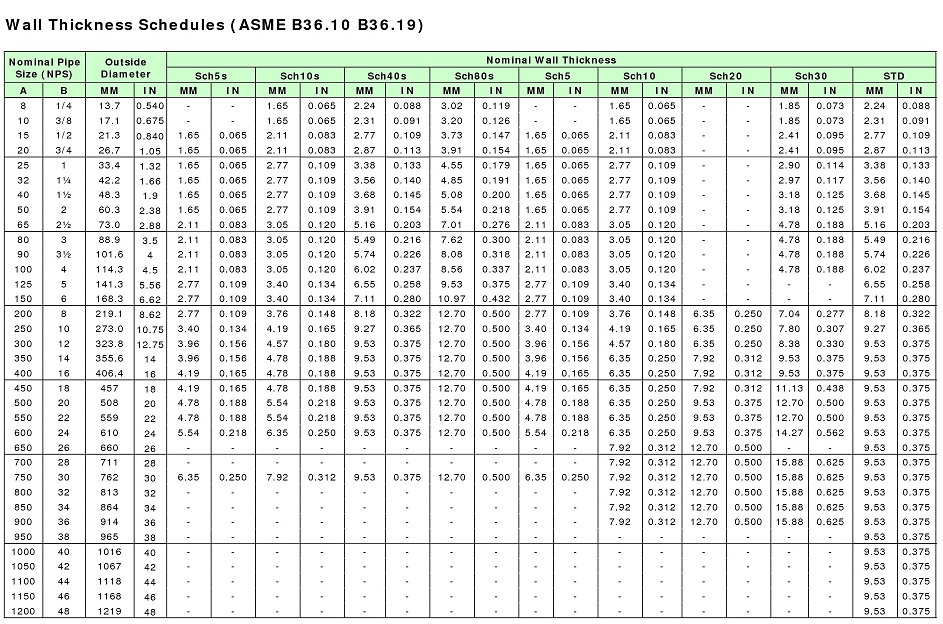

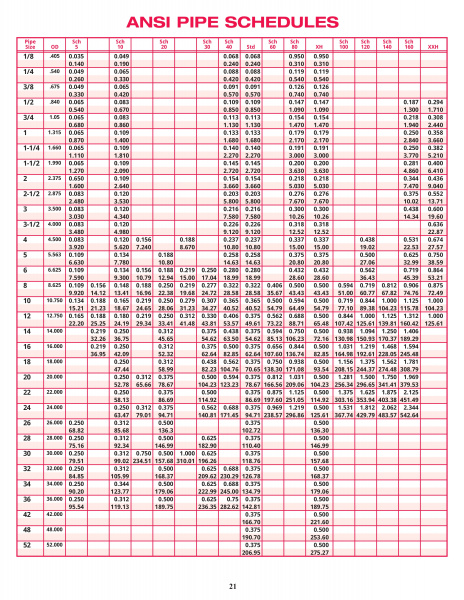

The "Schedule" designation for pipes, like Schedule 40, refers to a standardized system developed by the American Society of Mechanical Engineers (ASME) and detailed within the ASME B36.10M customary. This technique categorizes pipes primarily based on their wall thickness relative to their nominal diameter. Increased schedule numbers point out thicker partitions, and due to this fact better strain resistance. Schedule 40 is a typical alternative representing a stability between energy and value. Different schedules exist, together with Schedule 80 (thicker), Schedule 160 (even thicker), and decrease schedules like Schedule 10 (thinner), every with its personal particular functions.

The Schedule 40 Pipe Wall Thickness Chart:

The Schedule 40 wall thickness is not a single quantity; it varies relying on the nominal pipe dimension (NPS). The NPS is not the precise inside diameter (ID) however a nominal designation. The precise ID varies barely relying on the pipe materials and manufacturing tolerances. A Schedule 40 pipe wall thickness chart usually presents knowledge in tabular type, itemizing the NPS, the corresponding outdoors diameter (OD), wall thickness, and typically the within diameter. These charts are available on-line and in engineering handbooks.

Key Parameters within the Chart:

- Nominal Pipe Dimension (NPS): That is the usual dimension designation, not the exact measurement. It is essential to know {that a} 1-inch NPS pipe does not essentially have a 1-inch inside diameter.

- Exterior Diameter (OD): That is the precise outer diameter of the pipe, a continuing worth for a given NPS inside a particular schedule. This dimension is necessary for becoming choice and total system design.

- Wall Thickness: That is the essential parameter defining the Schedule 40 designation. It represents the gap from the inside to the outer floor of the pipe. It will increase with NPS, reflecting the necessity for better energy in bigger diameter pipes.

- Inside Diameter (ID): That is calculated by subtracting twice the wall thickness from the OD. The ID is necessary for figuring out stream capability and deciding on acceptable fittings and valves.

Decoding the Chart and its Implications:

The chart’s knowledge is crucial for a number of essential elements of pipe system design and implementation:

- Strain Score: Thicker partitions (larger schedules) translate to larger strain scores. Schedule 40 pipes are appropriate for reasonable to high-pressure functions, relying on the fluid and temperature. At all times seek the advice of related strain score charts for particular supplies and working circumstances.

- Structural Integrity: The wall thickness determines the pipe’s resistance to break down underneath exterior strain or bursting underneath inner strain. That is particularly vital in functions involving excessive pressures or important earth loading.

- Move Capability: The within diameter straight impacts the stream price of fluids inside the pipe. Smaller ID (thicker partitions) end in decreased stream capability in comparison with pipes with thinner partitions of the identical NPS.

- Materials Choice: The chart usually applies to varied supplies like metal, PVC, and others. Nevertheless, the precise wall thickness would possibly range barely relying on the fabric on account of manufacturing processes and materials properties. At all times check with producer specs for the exact dimensions of the chosen materials.

- Price Optimization: Increased schedule pipes are typically dearer because of the elevated materials utilization. Choosing the suitable schedule balances value with efficiency necessities. Over-specifying may be wasteful, whereas under-specifying can result in failure and security hazards.

Purposes of Schedule 40 Pipe:

Schedule 40 pipes discover widespread functions throughout numerous industries and sectors:

- Plumbing Methods: Residential, industrial, and industrial plumbing programs typically make the most of Schedule 40 pipes for water distribution, drainage, and waste disposal.

- Industrial Processes: They’re extensively utilized in chemical processing, manufacturing, and different industrial functions the place fluid switch is essential.

- Hearth Safety Methods: Schedule 40 pipes are generally utilized in hearth sprinkler and standpipe programs on account of their pressure-bearing capabilities.

- Pure Fuel Distribution: Schedule 40 pipes are employed in gasoline distribution networks, although larger schedules could be mandatory for higher-pressure functions.

- Irrigation Methods: In agricultural settings, Schedule 40 pipes are used for water distribution to crops.

- Building: They’re utilized in numerous development functions, together with constructing drainage, HVAC programs, and normal utility strains.

Limitations and Concerns:

Whereas Schedule 40 pipes provide a superb stability of energy and value, they’ve sure limitations:

- Not appropriate for all functions: For terribly high-pressure functions, larger schedules could be mandatory. For low-pressure functions, decrease schedules may be more cost effective.

- Materials limitations: The chart does not account for the particular properties of the pipe materials. Components like temperature, corrosion resistance, and chemical compatibility should be thought-about when deciding on the pipe materials.

- Manufacturing tolerances: Slight variations in dimensions can happen on account of manufacturing tolerances. At all times confirm the precise dimensions with the producer’s specs.

- Environmental components: Exterior components like soil circumstances, temperature fluctuations, and corrosive environments can have an effect on the pipe’s lifespan and efficiency.

Conclusion:

The Schedule 40 pipe wall thickness chart is a basic device for engineers, plumbers, and contractors concerned in pipe system design and set up. Understanding the chart’s parameters, implications, and limitations is essential for choosing the suitable pipe for a given utility, making certain structural integrity, and complying with security rules. At all times seek the advice of related requirements, producer specs, and engineering pointers to make sure the secure and environment friendly implementation of pipe programs. Ignoring these components can result in system failures, expensive repairs, and doubtlessly severe security hazards. Correct choice primarily based on an intensive understanding of the Schedule 40 chart and its context is paramount for profitable undertaking execution.

Closure

Thus, we hope this text has offered helpful insights into Decoding the Schedule 40 Pipe Wall Thickness Chart: A Complete Information. We recognize your consideration to our article. See you in our subsequent article!