Decoding the Sheet Metallic Bend Chart: A Complete Information

Associated Articles: Decoding the Sheet Metallic Bend Chart: A Complete Information

Introduction

On this auspicious event, we’re delighted to delve into the intriguing subject associated to Decoding the Sheet Metallic Bend Chart: A Complete Information. Let’s weave fascinating info and supply contemporary views to the readers.

Desk of Content material

Decoding the Sheet Metallic Bend Chart: A Complete Information

Sheet metallic bending is a elementary course of in manufacturing, used to create all kinds of components throughout quite a few industries. From automotive parts and electronics casings to aerospace components and medical units, precisely predicting bend dimensions is essential for environment friendly manufacturing and exact half performance. That is the place the sheet metallic bend chart turns into indispensable. This text delves deep into the intricacies of bend charts, explaining their objective, parts, how one can use them, and the components influencing their accuracy.

Understanding the Goal of a Sheet Metallic Bend Chart

A sheet metallic bend chart, also called a bend allowance chart or bend deduction chart, is a reference software that helps predict the ultimate dimensions of a sheet metallic half after bending. It accounts for the fabric’s deformation in the course of the bending course of, which leads to a change within the general size of the sheet metallic. And not using a bend chart, predicting the ultimate dimensions would rely solely on expertise and trial-and-error, resulting in potential materials waste, inaccurate components, and manufacturing delays. The chart gives a standardized technique for calculating the bend allowance, which is the quantity of fabric that’s compressed in the course of the bending operation.

Key Elements of a Sheet Metallic Bend Chart

A typical sheet metallic bend chart contains the next vital components:

-

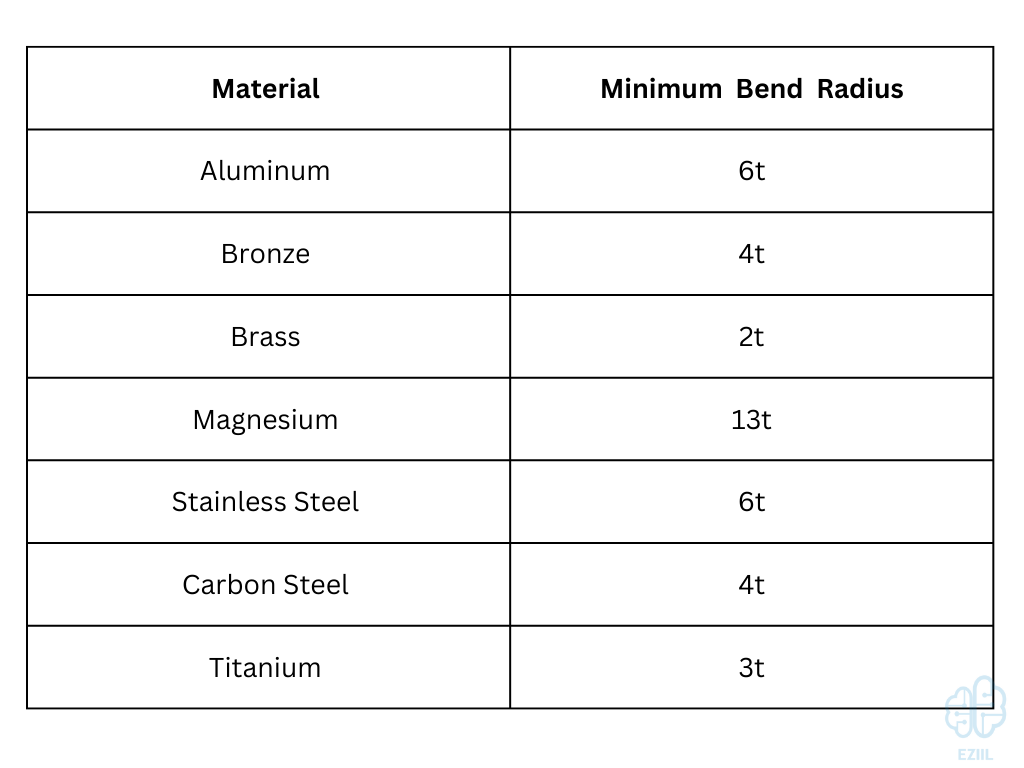

Materials Kind: That is arguably crucial issue. Totally different supplies (e.g., aluminum, metal, stainless-steel) have various properties, together with their springback, yield power, and ductility, all of which have an effect on the ultimate bend dimensions. The chart will specify the fabric’s grade and mood (e.g., 6061-T6 aluminum, 304 stainless-steel).

-

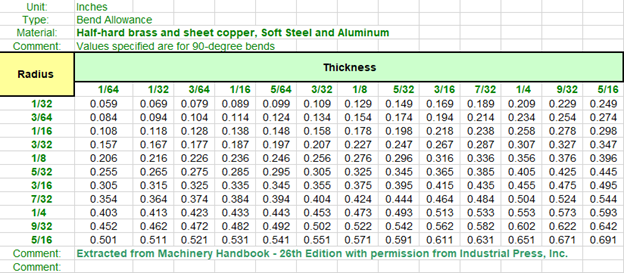

Materials Thickness: The thickness of the sheet metallic straight impacts the bend allowance. Thicker materials requires a bigger bend allowance in comparison with thinner materials. The chart often lists a variety of thicknesses or gives a method to calculate the bend allowance based mostly on thickness.

-

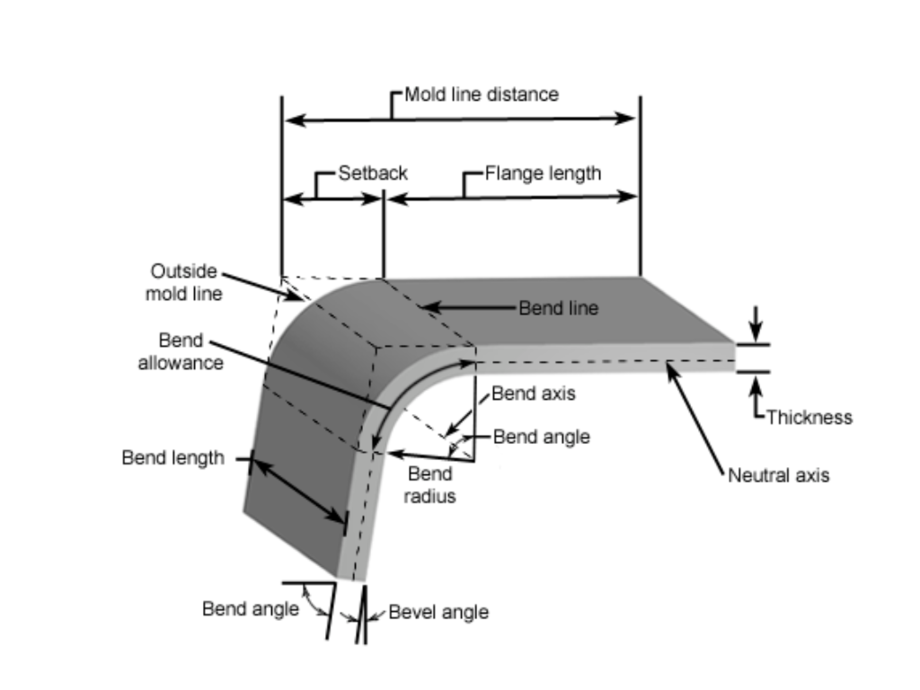

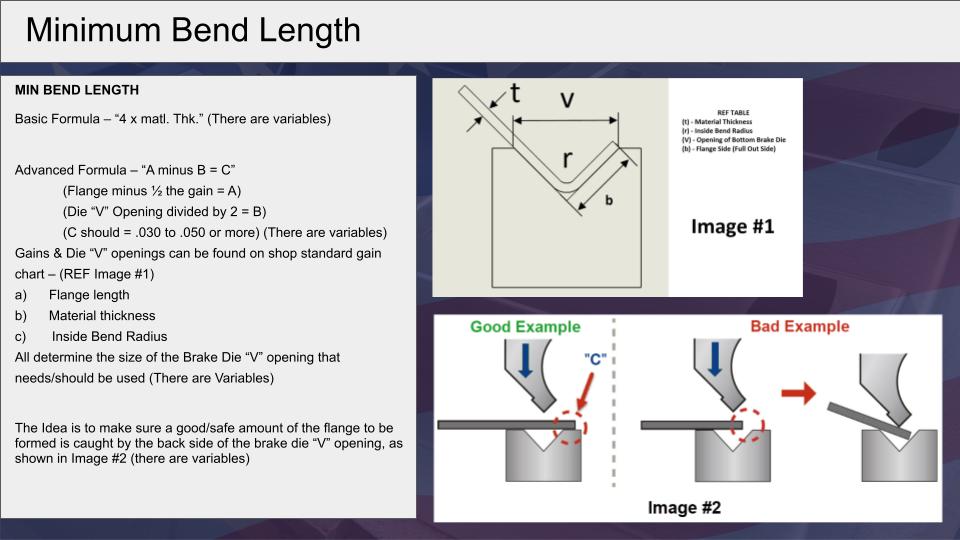

Bend Radius (R): The bend radius refers back to the radius of the interior curve of the bend. It is a vital parameter because it considerably influences the bend allowance. Smaller bend radii lead to extra materials compression and a bigger bend allowance. The chart typically gives information for various bend radii, categorized as inside radius (IR), exterior radius (OR), or bend radius (R). The connection between these radii and the fabric thickness can be essential.

-

Die Opening (V): The die opening, also called the V-opening or the gap between the punch and die, influences the bend angle. The chart might embrace information for varied die openings, exhibiting how they have an effect on the ultimate bend dimensions.

-

Bend Allowance (BA): That is the core calculation supplied by the chart. It represents the size of fabric consumed in the course of the bending course of. It is calculated based mostly on the fabric kind, thickness, bend radius, and desired bend angle.

-

Bend Deduction (BD): That is the quantity of fabric that must be subtracted from the flat clean size to realize the specified remaining dimensions. It is calculated because the distinction between the whole size of the straight components and the bend allowance.

-

Bend Angle (θ): This represents the angle fashioned between the 2 legs of the bend. The chart often gives information for traditional bend angles (e.g., 90°, 45°, 135°), nevertheless it may additionally embrace formulation for calculating bend allowance for any arbitrary angle.

-

Okay-Issue (Okay): The Okay-factor is a vital parameter that represents the ratio of the bend radius to the fabric thickness. It accounts for the fabric’s springback and is commonly empirically decided for a given materials and bending course of. The Okay-factor is utilized in many bend allowance formulation.

How you can Use a Sheet Metallic Bend Chart

Utilizing a bend chart is an easy course of, sometimes involving these steps:

-

Establish the Materials: Decide the precise materials kind and its mood or grade.

-

Specify the Materials Thickness: Notice the thickness of the sheet metallic getting used.

-

Outline the Bend Radius: Decide the within, exterior, or impartial bend radius.

-

Specify the Bend Angle: Decide the specified bend angle.

-

Find the Related Knowledge: Use the chart to seek out the bend allowance (BA) or bend deduction (BD) comparable to the required materials, thickness, bend radius, and bend angle.

-

Calculate the Flat Clean Size: Add the straight lengths of the half to the bend allowance (or subtract the bend deduction from the specified remaining size) to find out the required flat clean size earlier than bending.

Elements Affecting the Accuracy of Sheet Metallic Bend Charts

Whereas bend charts present a priceless estimation, a number of components can have an effect on their accuracy:

-

Springback: After bending, the fabric tends to partially get better its unique form, a phenomenon referred to as springback. That is influenced by materials properties, bend radius, and the bending course of itself. Correct prediction of springback requires exact information of fabric properties and infrequently includes empirical testing or refined finite aspect evaluation (FEA).

-

Materials Variations: Slight variations in materials properties inside a batch can have an effect on the bend allowance.

-

Bending Course of Variables: Elements such because the bending pace, tooling situation, and lubrication can all affect the ultimate bend dimensions.

-

Okay-Issue Variation: The Okay-factor just isn’t all the time fixed for a given materials and might range relying on the bending course of and tooling.

-

Air Bending vs. Backside Bending: Totally different bending methods (air bending, backside bending, coining) result in totally different bend allowances.

Superior Strategies and Concerns

For complicated components with a number of bends, the method turns into extra intricate. It could require iterative calculations or the usage of specialised software program that includes extra superior fashions to account for the interplay between a number of bends. Pc-aided design (CAD) software program typically contains built-in bend allowance calculation instruments that may deal with complicated geometries and a number of bends extra successfully than easy charts.

Conclusion

Sheet metallic bend charts are important instruments for correct prediction of bent half dimensions. Whereas they provide a simplified method, understanding their limitations and the components that affect their accuracy is essential. By fastidiously contemplating materials properties, bending parameters, and potential springback, producers can leverage bend charts to optimize their processes, scale back materials waste, and enhance the general high quality and consistency of their sheet metallic components. For complicated geometries or high-precision necessities, integrating superior methods and software program is really helpful to make sure correct and environment friendly manufacturing. In the end, the efficient use of a bend chart, coupled with sensible expertise and an intensive understanding of the bending course of, is vital to profitable sheet metallic fabrication.

Closure

Thus, we hope this text has supplied priceless insights into Decoding the Sheet Metallic Bend Chart: A Complete Information. We hope you discover this text informative and useful. See you in our subsequent article!