Understanding and Making use of the c-Chart in High quality Management

Associated Articles: Understanding and Making use of the c-Chart in High quality Management

Introduction

With nice pleasure, we’ll discover the intriguing subject associated to Understanding and Making use of the c-Chart in High quality Management. Let’s weave attention-grabbing info and provide contemporary views to the readers.

Desk of Content material

Understanding and Making use of the c-Chart in High quality Management

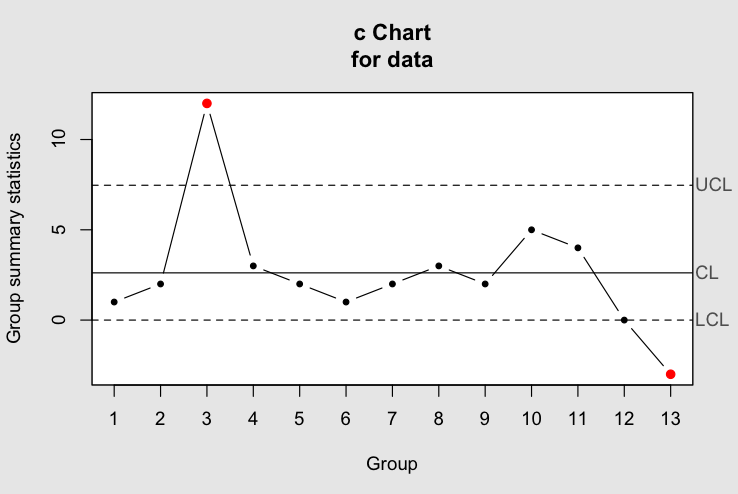

The c-chart, a robust statistical course of management (SPC) software, is particularly designed for monitoring the variety of defects present in a pattern of fixed dimension. Not like p-charts or np-charts which monitor the proportion or variety of faulty gadgets, the c-chart focuses on the variety of defects inside a single unit or a set pattern dimension. This distinction is essential, as a single unit can comprise a number of defects. Consider a chunk of material with a number of blemishes, a circuit board with a number of defective elements, or a manufactured product with varied imperfections. In these eventualities, the c-chart supplies a worthwhile methodology for monitoring and enhancing high quality.

This text will delve into the intricacies of c-charts, explaining their software, building, interpretation, and limitations. We’ll discover the underlying statistical assumptions, reveal the method with sensible examples, and focus on learn how to use c-charts successfully to boost high quality management procedures.

Understanding the Underlying Rules:

The c-chart depends on the Poisson distribution, a likelihood distribution that describes the likelihood of a given variety of occasions occurring in a set interval of time or house if these occasions happen with a recognized common fee and independently of the time because the final occasion. This assumption is essential as a result of it underpins the calculation of management limits and the interpretation of the chart. The Poisson distribution is acceptable when:

- Defects happen randomly: The prevalence of 1 defect would not affect the likelihood of one other defect occurring.

- The typical variety of defects is comparatively fixed: The method is in a state of statistical management, that means the underlying causes of defects are constant over time.

- The pattern dimension is fixed: The variety of models inspected stays the identical for every pattern.

If these assumptions are violated, the c-chart could not present correct outcomes, and various management charts may be extra appropriate.

Developing a c-Chart:

Developing a c-chart includes a number of key steps:

-

Information Assortment: Accumulate knowledge on the variety of defects present in every pattern. Make sure the pattern dimension stays fixed all through the information assortment course of. For instance, you may examine 100 circuit boards and report the variety of defects discovered on every board.

-

Calculating the Common Variety of Defects (c-bar): Sum the entire variety of defects throughout all samples and divide by the variety of samples. This provides you the typical variety of defects per pattern, denoted as

c-bar(ē).c-bar = Σcᵢ / nThe place:

-

Σcᵢis the sum of the variety of defects in every pattern. -

nis the variety of samples.

-

-

Calculating the Management Limits: The management limits outline the vary inside which the variety of defects is taken into account to be in statistical management. The management limits are calculated utilizing the next formulation:

-

Higher Management Restrict (UCL):

c-bar + 3√c-bar -

Decrease Management Restrict (LCL):

c-bar - 3√c-bar

Using 3 normal deviations (3√c-bar) supplies roughly 99.73% confidence that factors falling inside these limits symbolize a secure course of. Nevertheless, if the calculated LCL is detrimental, it is conventionally set to zero, as you can not have a detrimental variety of defects.

-

Higher Management Restrict (UCL):

-

Plotting the Chart: Plot the variety of defects for every pattern on the chart, with the pattern quantity on the x-axis and the variety of defects on the y-axis. Draw horizontal strains representing the

c-bar, UCL, and LCL.

Decoding the c-Chart:

As soon as the c-chart is constructed, interpretation includes analyzing the plotted factors relative to the management limits:

- Factors throughout the management limits: Point out that the method is in statistical management. The variety of defects is in line with the typical and variations are inside anticipated random fluctuations.

- Factors outdoors the management limits: Counsel that the method is uncontrolled. This means a major shift within the common variety of defects, doubtlessly brought on by assignable causes (particular, identifiable components contributing to elevated defects). Investigation is critical to establish and get rid of these causes.

- Non-random patterns: Even when all factors stay throughout the management limits, non-random patterns (e.g., tendencies, cycles, stratification) can point out underlying points that warrant investigation. These patterns recommend that the method could also be drifting towards instability, even when it hasn’t but crossed the management limits.

Sensible Instance:

Let’s contemplate a producing course of producing circuit boards. We examine 50 boards every day for 5 days and report the variety of defects discovered:

- Day 1: 12 defects

- Day 2: 15 defects

- Day 3: 10 defects

- Day 4: 13 defects

- Day 5: 14 defects

-

c-bar: (12 + 15 + 10 + 13 + 14) / 5 = 12.8 defects

-

UCL: 12.8 + 3√12.8 ≈ 21.6

-

LCL: 12.8 – 3√12.8 ≈ 4.0 (Since LCL can’t be detrimental, it is rounded as much as 0)

Plotting these values on a c-chart would enable for visible inspection of the method stability. If any day confirmed a defect depend exceeding 21.6 or under 0, it could sign an out-of-control situation requiring investigation.

Benefits and Limitations of c-Charts:

Benefits:

- Simplicity: Comparatively straightforward to know and assemble.

- Effectiveness: Offers a transparent visible illustration of course of stability concerning defect charges.

- Early warning system: Permits for early detection of course of shifts, stopping the manufacturing of faulty gadgets.

- Focused enchancment: Helps pinpoint areas needing enchancment by figuring out the foundation causes of defects.

Limitations:

- Fixed pattern dimension: Requires a continuing pattern dimension for every pattern, which can not all the time be possible.

- Poisson distribution assumption: The accuracy of the c-chart depends on the belief of a Poisson distribution, which can not all the time maintain true in real-world eventualities.

- Would not establish the kind of defect: Solely signifies the variety of defects, not the particular kinds of defects. Additional evaluation is required to know the character of the defects.

- Ignoring defect severity: All defects are handled equally, no matter their severity. A weighted c-chart may be extra acceptable if defect severity varies considerably.

Conclusion:

The c-chart is a worthwhile software in high quality management for monitoring the variety of defects in a constant-size pattern. Its simplicity and effectiveness make it a extensively used methodology for figuring out and addressing course of instability. Nevertheless, it is essential to know its underlying assumptions and limitations to make sure correct interpretation and efficient software. By fastidiously accumulating knowledge, developing the chart accurately, and deciphering the outcomes thoughtfully, organizations can leverage the c-chart to enhance product high quality, scale back waste, and improve general effectivity. Keep in mind that the c-chart is only one software in a broader high quality administration system, and its use must be complemented by different strategies for a complete strategy to high quality management.

Closure

Thus, we hope this text has supplied worthwhile insights into Understanding and Making use of the c-Chart in High quality Management. We thanks for taking the time to learn this text. See you in our subsequent article!